Is carbon steel strong?

Carbon steel is a widely used material in many industries, from construction to manufacturing. However, there is a common misconception that carbon steel is not as strong as other metals. Let me tell you a story about a young engineer who was tasked with designing a new building. They were hesitant to use carbon steel because of its reputation for being weaker than other materials. But with some research and experimentation, they discovered that carbon steel can be just as strong and durable as other metals when used correctly.

So Is carbon steel strong?

The answer is yes, carbon steel can be strong and durable, depending on the specific type and how it’s used. The strength of carbon steel depends on factors such as the amount of carbon, the manufacturing process, and the treatment it receives. Carbon steel is commonly used in industries such as construction, automotive, and manufacturing due to its strength and affordability.

However, it’s important to choose the right type of carbon steel for your specific application to ensure optimal strength and performance.

In this article, we’ll explore the truth about carbon steel’s strength and how it can be used in various applications. Let’s dive in and uncover the facts about carbon steel’s strength.

I. Introduction

Carbon steel is a widely used material in many industries due to its durability, versatility, and affordability. It is a type of steel that contains carbon as the main alloying element, with other elements added to improve its mechanical properties. In this article, we will explore the question “Is carbon steel strong?” and examine the factors that contribute to its strength.

The purpose of this article is to provide a comprehensive overview of carbon steel and its strength. We will discuss the different types of carbon steel, their compositions, and their properties. Additionally, we will explore the advantages and disadvantages of using carbon steel in various applications and provide tips for maintaining its strength over time.

This article is especially relevant to those in industries that rely heavily on carbon steel, such as construction, manufacturing, and automotive. Carbon steel suppliers, in particular, can benefit from a better understanding of the properties of this material to better serve their customers.

In the following sections, we will discuss the composition and strength of carbon steel, the factors that affect its strength, the different types of carbon steel, and their applications. We will also explore the advantages and disadvantages of using carbon steel and provide tips for maintaining its strength.

By the end of this article, readers will have a comprehensive understanding of carbon steel and its strength, and be better equipped to make informed decisions about using this material in their applications.

By Huaxia-steel – Carbon Steel Suppliers

II. Composition of Carbon Steel

Carbon steel is an alloy of iron and carbon, with the carbon content typically ranging from 0.05% to 2.0%. In addition to carbon, other elements such as manganese, silicon, and sulfur can also be present in varying amounts. The composition of carbon steel plays a crucial role in determining its strength and other physical properties.

A. Overview of the composition of carbon steel

Carbon steel can be broadly classified into low carbon steel, medium carbon steel, and high carbon steel based on their carbon content. Low carbon steel, also known as mild steel, typically contains less than 0.3% carbon and is the most commonly used form of carbon steel due to its low cost and good formability.

Medium carbon steel contains between 0.3% to 0.6% carbon and has higher strength compared to low carbon steel. High carbon steel contains more than 0.6% carbon and is known for its high strength, hardness, and wear resistance.

B. Explanation of how the different elements in carbon steel affect its strength

The different elements present in carbon steel can have a significant impact on its strength. For example, manganese is often added to improve the strength and toughness of carbon steel, while silicon is added to improve its resistance to oxidation and corrosion. Sulfur and phosphorus are impurities that can adversely affect the strength of carbon steel and therefore are typically kept at low levels.

C. Role of carbon in carbon steel strength

Carbon is the most important element in determining the strength of carbon steel. As the carbon content increases, the strength and hardness of the steel also increase. However, increasing the carbon content beyond a certain point can result in reduced ductility and toughness. Therefore, the carbon content is carefully balanced to achieve the desired combination of strength, hardness, and ductility.

D. Importance of sourcing from reputable carbon steel suppliers

The composition of carbon steel can vary depending on the source and manufacturing process. Therefore, it is crucial to source carbon steel from reputable suppliers who can provide consistent quality and composition. Choosing the right carbon steel suppliers can ensure that the carbon steel used in the applications is strong and reliable.

In conclusion, understanding the composition of carbon steel is essential in determining its strength and other physical properties. The different elements present in carbon steel can have a significant impact on its strength, and therefore, careful consideration must be given to sourcing from reputable carbon steel suppliers to ensure the desired properties are achieved.

By Huaxia-steel – Carbon Steel Suppliers

III. Strength of Carbon Steel

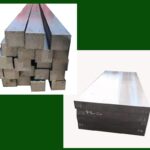

Carbon steel is known for its strength and durability, making it a popular choice for various applications. In this section, we will discuss the strength of carbon steel, how it is measured, and how it compares to other materials.

A. Overview of the strength of carbon steel

Carbon steel is strong and rigid, making it ideal for use in construction and manufacturing. The strength of carbon steel depends on the composition of the steel and the manufacturing process. Carbon steel with higher levels of carbon has increased strength, but also becomes more brittle.

B. Explanation of how the strength of carbon steel is measured

The strength of carbon steel is typically measured in terms of its yield strength, tensile strength, and elongation. Yield strength is the amount of stress required to deform the steel, while tensile strength is the maximum amount of stress the steel can handle before breaking. Elongation is the amount of deformation the steel can undergo before it breaks. These measurements are important for determining the suitability of carbon steel for specific applications.

C. Comparison of the strength of carbon steel to other materials

Carbon steel is one of the strongest materials available, with a tensile strength of up to 1500 megapascals. It is stronger than most other metals, including aluminum, copper, and brass. However, carbon steel is not as strong as materials such as titanium or high-strength alloys.

When choosing a carbon steel supplier, it is important to consider the specific strength requirements for your application. Some suppliers may specialize in certain types of carbon steel or have unique manufacturing processes that can affect the strength of the steel.

Overall, carbon steel’s strength and durability make it a popular choice for various applications. In the next section, we will discuss the factors that can affect the strength of carbon steel.

By Huaxia-steel – Carbon Steel Suppliers

IV. Factors Affecting Carbon Steel Strength

Carbon steel is a versatile and widely used material due to its strength, durability, and cost-effectiveness. However, there are several factors that can affect its strength and performance. Here are some important factors to consider:

- Carbon Content:

The carbon content in carbon steel is the primary factor affecting its strength. As the carbon content increases, the steel becomes stronger and harder but less ductile. - Alloying Elements:

The addition of alloying elements such as manganese, chromium, nickel, and molybdenum can increase the strength and hardness of carbon steel. The effect of these elements on the strength of carbon steel depends on their concentration and the type of alloy. - Heat Treatment:

Heat treatment is the process of heating and cooling the steel to change its microstructure and properties. Different heat treatment methods, such as quenching, tempering, and annealing, can affect the strength and toughness of carbon steel. - Manufacturing Process:

The manufacturing process used to produce carbon steel can also affect its strength. For example, the hot-rolling process can produce stronger and tougher steel than the cold-rolling process. - Welding and Joining:

Welding and joining can affect the strength and performance of carbon steel. Improper welding can cause defects such as cracks and porosity, which can weaken the steel.

It is important to consider these factors when selecting carbon steel for an application. Additionally, proper quality control measures must be taken by carbon steel suppliers to ensure that the steel meets the required specifications for strength and performance.

It is also important to note that the factors affecting the strength of carbon steel can vary depending on the type of carbon steel. For example, high-carbon steel has different properties than low-carbon steel, and therefore may have different factors affecting its strength.

In conclusion, the strength and performance of carbon steel can be affected by various factors, including carbon content, alloying elements, heat treatment, manufacturing process, and welding and joining. Proper consideration of these factors and quality control measures by carbon steel suppliers can ensure the strength and durability of the material.

By Huaxia-steel – Carbon Steel Suppliers

V. Types of Carbon Steel

Carbon steel is a versatile material that comes in different types, each with unique characteristics that make them suitable for specific applications. In this section, we will discuss the different types of carbon steel, their strength, and applications.

- Low Carbon Steel:

Low carbon steel, also known as mild steel, is the most commonly used type of carbon steel due to its low cost and versatility. It has a carbon content of up to 0.3%, making it relatively soft and easy to shape. Low carbon steel is used in a wide range of applications, such as construction, automotive, and manufacturing. - Medium Carbon Steel:

Medium carbon steel has a higher carbon content than low carbon steel, ranging from 0.3% to 0.6%. It is stronger and more durable than low carbon steel, but also less malleable. Medium carbon steel is commonly used in applications that require high tensile strength, such as machinery and tools. - High Carbon Steel:

High carbon steel has a carbon content of 0.6% to 1.5%, making it the strongest and most durable type of carbon steel. It is hard and brittle, making it difficult to shape and weld, but ideal for applications that require extreme strength and durability, such as knives and cutting tools. - Ultra-High Carbon Steel:

Ultra-high carbon steel has a carbon content of over 1.5%, making it the strongest and hardest type of carbon steel. It is extremely brittle and difficult to shape, but has excellent wear resistance, making it ideal for applications such as bearings, springs, and cutting tools. - Alloy Steel:

Alloy steel is a type of carbon steel that contains additional elements such as chromium, nickel, and manganese. These elements improve the strength and durability of carbon steel, making it suitable for applications that require high performance, such as aerospace and defense industries.

When choosing the right type of carbon steel for your application, it is important to consider factors such as strength, durability, and cost. Carbon steel suppliers can help you identify the best type of carbon steel for your specific needs and provide you with the necessary information to make an informed decision.

In conclusion, the type of carbon steel chosen for a particular application depends on the requirements of that application. Low carbon steel is ideal for applications that require low strength and malleability, while high carbon steel is best suited for applications that require high strength and durability. By working with carbon steel suppliers, you can ensure that you are using the right type of carbon steel for your specific application, resulting in a strong and durable end product.

By Huaxia-steel – Alloy Steel Suppliers

VI. Advantages and Disadvantages of Carbon Steel

Carbon steel is a popular material used in various industries due to its many advantages, such as its strength, durability, and cost-effectiveness. However, it also has some disadvantages that should be considered before deciding to use it in certain applications.

Advantages:

- Strength:

Carbon steel is known for its strength and durability, making it ideal for applications that require a high level of toughness. - Cost-effective:

Carbon steel is relatively inexpensive compared to other materials, making it a popular choice for large-scale projects. - Versatile:

Carbon steel can be easily machined, welded, and formed into different shapes, making it a versatile material for various applications. - Resistant to corrosion:

Carbon steel can be made more resistant to corrosion by adding different elements such as chromium and nickel.

Disadvantages:

- Prone to rust:

Carbon steel is not as resistant to rust as other materials, so it requires proper maintenance to prevent corrosion. - Brittle:

Carbon steel can become brittle when exposed to high temperatures or when it undergoes repeated stress, which can lead to cracking and failure. - Limited heat resistance:

Carbon steel is not suitable for high-temperature applications as it can deform or lose its strength at high temperatures. - Environmental concerns:

The production of carbon steel can have negative environmental impacts due to its high carbon emissions and energy consumption.

When considering using carbon steel for your application, it is important to weigh the advantages and disadvantages and decide whether it is the right material for your needs.

If you decide to use carbon steel, it is important to find reputable carbon steel suppliers who can provide high-quality materials that meet your specifications. Look for suppliers who have a good reputation and who can provide documentation to prove the quality and composition of their products.

In conclusion, carbon steel is a strong and versatile material that has many advantages and disadvantages. It is important to weigh these factors carefully and consider finding reliable carbon steel suppliers to ensure the strength and quality of your materials.

By Huaxia-steel – Carbon Steel Suppliers

VII. Maintaining the Strength of Carbon Steel

Carbon steel is known for its strength and durability, but it requires proper maintenance to maintain its strength over time. In this section, we will discuss some tips for maintaining the strength of carbon steel and how improper maintenance can affect the strength of carbon steel.

- Keep carbon steel clean:

Regular cleaning is essential to maintain the strength of carbon steel. Dirt, grime, and other contaminants can cause corrosion and weaken the steel. Use a mild detergent and warm water to clean carbon steel. Avoid using abrasive cleaners that can scratch the surface of the steel. - Dry carbon steel after cleaning:

After cleaning carbon steel, make sure to dry it thoroughly to prevent rust and corrosion. Use a clean, dry cloth to wipe the steel dry. If the steel is not completely dry, it can develop rust spots that can weaken the steel over time. - Store carbon steel in a dry place:

Proper storage is important to maintain the strength of carbon steel. Store carbon steel in a dry place to prevent exposure to moisture, which can cause rust and corrosion. If you must store carbon steel in a damp or humid area, make sure to keep it covered with a waterproof material. - Apply a protective coating:

Applying a protective coating, such as a rust inhibitor or paint, can help to protect carbon steel from rust and corrosion. Make sure to choose a coating that is appropriate for the specific type of carbon steel you are using.

Improper maintenance can significantly impact the strength of carbon steel. Here are some ways in which improper maintenance can affect carbon steel:

- Rust and corrosion:

If carbon steel is not properly cleaned and dried, it can develop rust and corrosion. This can weaken the steel and reduce its overall strength. - Pitting:

Pitting is a type of corrosion that can occur on carbon steel. It can weaken the steel and cause it to fail over time. - Cracking:

Improper maintenance can cause carbon steel to crack. This can occur due to exposure to extreme temperatures, stress, or other factors.

In conclusion, proper maintenance is essential to maintain the strength of carbon steel. By following the tips outlined in this section, you can help to ensure that your carbon steel remains strong and durable over time. If you need assistance with maintaining your carbon steel, reach out to carbon steel suppliers for guidance and advice. They can provide you with the information and resources you need to keep your carbon steel strong and reliable for years to come.

Part VIII. Conclusion

Carbon steel is a versatile and widely used material due to its excellent strength and durability. This article has provided an overview of carbon steel, including its composition, strength, factors affecting its strength, types, advantages and disadvantages, and tips for maintaining its strength.

In conclusion, carbon steel is a strong and reliable material that can be used in various applications, from construction to manufacturing. Its strength and durability make it an ideal choice for many industries. However, it is important to note that improper maintenance can affect its strength and longevity. Therefore, it is crucial to follow proper maintenance procedures to ensure the longevity of carbon steel components.

For those considering using carbon steel in their applications, it is important to work with reputable carbon steel suppliers who can provide high-quality materials. These suppliers can help you choose the right type of carbon steel for your specific needs and provide you with the necessary support and guidance throughout the process.

Overall, carbon steel remains one of the strongest and most reliable materials available today. With proper care and maintenance, carbon steel components can last for many years, providing a cost-effective and durable solution for a variety of applications.

By Huaxia-steel – Carbon Steel Suppliers

Related Blogs

Steel Pipe vs Steel Tube: Key Differences and Applications

Discover the key differences between steel pipes and steel tubes, including their uses, measurements, and schedules like schedule 40 vs schedule 80 pipes. Learn which is right for your project and how to choose the best steel solution.

General Materials of Honed Tubes

Honed tubes are typically made from materials such as carbon steel, alloy steel, stainless steel, and special alloys. Carbon steel, like ST52 and 45#, is widely used for its strength and affordability, making it ideal for hydraulic and pneumatic systems. Alloy steel, including grades like 16Mn and 27SiMn, offers enhanced wear resistance and strength for high-pressure applications. Stainless steel, such as 304 and 316, is favored for its corrosion resistance, especially in harsh environments. Special alloys like Inconel and Hastelloy are used in extreme conditions where high temperatures or corrosion resistance is essential, such as in marine and chemical industries.

The Relationship Between Carbon Steel and Tool Steel

Carbon steel and tool steel are two fundamental types of steel, each with its own specific properties and applications. While they share some similarities—both being forms of steel with varying carbon content—they serve very different purposes in industrial and manufacturing contexts. Understanding the relationship between carbon steel and tool steel can help clarify their unique roles and why each is chosen for specific applications.

Table of Contents

Request A Free Quote

Request A Free Quote

We’d like to work with you

By Huaxia-steel – Alloy Steel Suppliers

If you require further information about our metal sheet products or architectural projects, please don’t hesitate to leave your contact details and message here.

Our team of experts will respond within 24 hours to continue the discussion and provide you with any additional information you requires.