Knowledge: What is Carbon Steel?

Carbon steel is an essential material used in various industries due to its exceptional durability and strength. Whether it’s constructing buildings or creating tools, carbon steel is a vital component. Have you ever wondered what makes carbon steel stand out from other materials? In this article, we’ll delve into the basics of carbon steel, from its composition to its practical applications. Whether you’re an engineer, a DIY enthusiast, or simply curious about materials, you’ll learn everything you need to know about carbon steel. Let’s start exploring the world of carbon steel together!

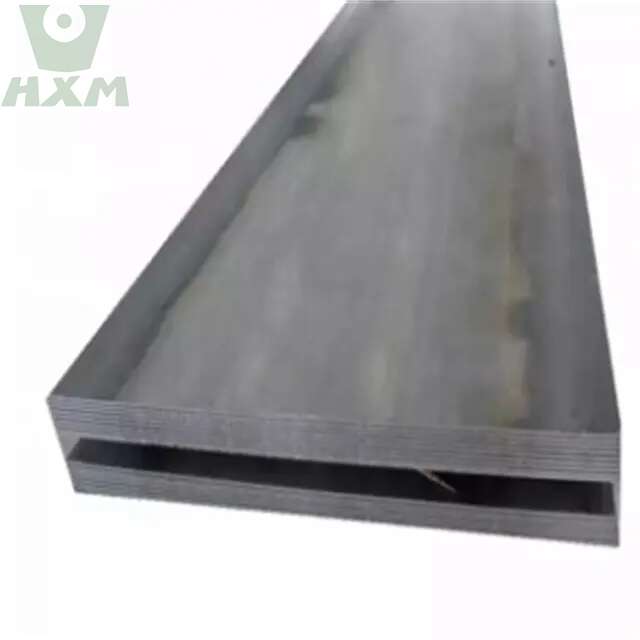

Carbon steel is an alloy of iron and carbon. It is a strong, durable, and cost-effective material commonly used in construction, manufacturing, and other industrial applications. Carbon steel can be further divided into various grades based on its carbon content, which affects its strength, hardness, and ductility.

In this article, we will discuss this question from the following parts:

Contents

Classification of Carbon Steel

Carbon steel can be classified into several types based on its carbon content, including:

1. Low carbon steel:

This type of carbon steel contains a carbon content of up to 0.3%. It is the most common type of carbon steel and is used in a variety of applications, including construction and manufacturing.

2. Medium carbon steel:

This type of carbon steel contains a carbon content ranging from 0.3% to 0.6%. It offers higher strength and hardness than low carbon steel and is often used for the production of automotive parts and machinery.

3. High carbon steel:

This type of carbon steel contains a carbon content ranging from 0.6% to 1.4%. It is very hard and strong, but also brittle, and is commonly used for the production of cutting tools, knives, and springs.

4. Ultra-high carbon steel:

This type of carbon steel contains a carbon content ranging from 1.4% to 2.0%. It is extremely hard and brittle and is used in very specific applications, such as the production of high-quality knives.

The classification of carbon steel is based on its carbon content, which determines the steel’s properties, including its strength, hardness, and ductility. The type of carbon steel used in a particular application will depend on the specific requirements of the application and the desired properties of the steel.

What is carbon steel used for?

Carbon steel is widely used in many industries, including construction, manufacturing, heavy industry, automotive, and oil and gas. Some common applications of carbon steel include:

- Steel structures:

Carbon steel is used to make the structural components of buildings, bridges, and other structures, such as steel beams, columns, and trusses. - Piping and tubing:

Carbon steel is used to make pipes and tubes for a variety of applications, including oil and gas transportation, water supply, and sewage systems. - Machine parts:

Carbon steel is used to make machine parts for a wide range of equipment, from small household appliances to heavy machinery, such as gears, shafts, and bearings. - Tools:

Carbon steel is used to make tools, such as saw blades, drill bits, and hand tools, due to its strength and durability. - Automotive components:

Carbon steel is used in the production of various components for cars and trucks, such as suspension components, body panels, and frames. - Offshore drilling equipment:

Carbon steel is used in the production of offshore drilling equipment, such as oil rigs and platforms, due to its strength and durability in harsh environments.

-1.jpg)

.png)

-1.jpg)

.png)

.png)

Conclusion

While carbon steel is strong and durable, it is also more susceptible to corrosion compared to stainless steel. In order to protect carbon steel from corrosion, various methods can be used, such as painting, galvanizing, and the use of coatings. In addition, some types of carbon steel, such as low-carbon steels, may be susceptible to stress corrosion cracking, which is a type of corrosion that occurs under the combined action of stress and a corrosive environment.

To sum up, carbon steel is an important and widely used material in many industries due to its low cost, strength, and versatility. However, its susceptibility to corrosion means that it may require additional protection in certain environments, and its properties must be carefully considered when selecting it for specific applications.

Request A Free Quote

We’d like to work with you

If you require further information about our metal sheet products or architectural projects, please don’t hesitate to leave your contact details and message here.

Our team of experts will respond within 24 hours to continue the discussion and provide you with any additional information you requires.