Carbon Steel

Huaxia-steel——Carbon Steel Supplier

Carbon steel is classified according to carbon content and is divided into low carbon steel, medium carbon steel and high carbon steel. Each category includes a range of grades with specific carbon content and corresponding product performance standards commonly used in the industry.

| Classification | Carbon Content | Grades | Product Execution Standards |

|---|---|---|---|

| Low Carbon Steel | 0.05% – 0.30% | ASTM A36, ASTM A283, ASTM A572, ASTM A573, SAE 1008, SAE 1010, SAE 1015, SAE 1020, SAE 1025, SAE 1030 | ASTM A36, ASTM A283, GB/T 700 |

| Medium Carbon Steel | 0.30% – 0.60% | AISI 1045, AISI 1050, AISI 1055, AISI 1060, AISI 1065, AISI 1070, AISI 1075, AISI 1080, AISI 1084, AISI 1085, DIN C45, JIS S45C | ASTM A29, ASTM A108, GB/T 699 |

| High Carbon Steel | 0.60% – 1.00% | AISI 1095, AISI 1086, AISI 1090, AISI 1095, AISI 1098, AISI 1099, AISI 1541, DIN 1.1210, DIN 1.1231, DIN 1.1248, JIS S50C | ASTM A29, ASTM A682, GB/T 699 |

applications of carbon steel

Low Carbon Steel:

- Application: Structural components in construction, automotive body panels and frames.

Medium Carbon Steel:

- Application: Machinery parts such as gears, crankshafts, and axles.

High Carbon Steel:

- Application: Cutting tools like knives and saw blades, as well as springs and suspension components.

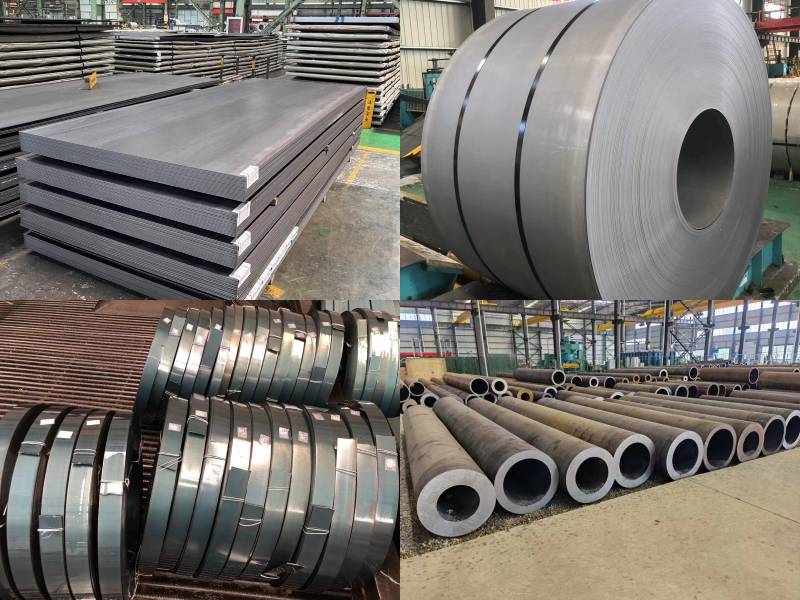

At Huaxia-steel, we are reliable carbon steel suppliers that offers a wide range of high-quality carbon steel products to meet the needs of industrial applications. Our carbon steel pipes and tubes are made from top-grade materials, ensuring durability and long-lasting performance. We offer a range of carbon steel products, including seamless and welded pipes and tubes, as well as fittings and accessories.

We are committed to delivering the highest quality carbon steel products at competitive prices. Whether you need standard or custom carbon steel products, we have the expertise and resources to deliver them. Partner with Huaxia-steel for your carbon steel needs and experience reliable, high-quality products and exceptional customer service.

Carbon steel, named for its high carbon content, is a popular material in many industries due to its durability, strength, and affordability. Used in construction, manufacturing, and transportation, carbon steel is a versatile material that can be shaped into a variety of products. Huaxia-steel offers a wide range of carbon steel products, including pipes, tubes, and plates, to meet the needs of our customers worldwide.

Grades of carbon steel

4 Key Differences Between Carbon Steel and Alloy Steel

When it comes to choosing the right type of steel for industrial applications, understanding the differences between carbon steel and alloy steel is crucial. These two categories of steel offer distinct properties, and knowing how they differ can help manufacturers, engineers, and buyers select the most suitable material for their needs. Below, we explore the 4 key differences between carbon steel and alloy steel.

4 Differences between Hot-rolled Carbon Steel and Cold-rolled Carbon Steel

Hot rolling and cold roll

REQUEST A QUOTE FOR MORE DETAILS

All You Need To Know About Carbon Steel

Let’s talk about carbon steel – the unsung hero of the manufacturing world. It’s an alloy that’s made by combining carbon and iron, and it’s one of the most widely used materials in the industry.

First off, let’s discuss its benefits. Carbon steel is known for its strength, durability, and low cost. It’s used to make everything from car parts to kitchen knives. But what sets it apart from other materials is its versatility – it can be easily modified to suit different needs. For instance, adding more carbon to the alloy increases its strength and hardness.

However, like everything else, it has its downsides. Carbon steel is susceptible to rust, which is why manufacturers often add coatings to protect it. It’s also prone to warping and cracking if it’s not cooled or heated correctly during the manufacturing process.

Now, let’s talk about the different types of carbon steel. The most commonly used ones are low carbon, medium carbon, and high carbon steel. Low carbon steel is malleable and easy to work with, but it’s not as strong as other types. High carbon steel is extremely hard and durable, but it’s also brittle, which makes it difficult to work with.

Finally, let’s discuss the quality control process for carbon steel. Manufacturers use a variety of techniques to ensure that the steel meets the required quality standards. They check for defects like cracks, warps, and impurities that can affect the steel’s strength and durability. Quality control is crucial because using low-quality carbon steel in manufacturing or construction can have serious consequences, including safety hazards and product failure.

So there you have it, everything you need to know about carbon steel. It’s a versatile, durable, and cost-effective material that’s used in countless applications across various industries. But, as with anything else, quality control is key to ensuring that it performs at its best.

What is carbon steel used for?

Carbon steel has a wide range of applications due to its excellent mechanical properties and affordability. It is commonly used in:

- Construction and building industry:

Carbon steel is used for reinforcing bars, structural steel, and other construction materials. - Manufacturing industry:

Carbon steel is used for machinery parts, tools, and equipment due to its high strength and durability. - Transportation industry:

Carbon steel is used in the manufacturing of cars, trucks, and trains due to its strength and ability to withstand high temperatures. - Energy industry:

Carbon steel is used in the production of pipelines, drilling equipment, and storage tanks due to its high strength and resistance to corrosion. - Other industries:

Carbon steel is also used in the production of cookware, knives, and other household items.

How strong is carbon steel?

Carbon steel is a popular material in various industries due to its strength, durability, and affordability. The strength of carbon steel depends on its carbon content and the specific heat treatment applied during manufacturing. Carbon steel is generally classified into low, medium, and high carbon content, with each type having different strength characteristics.

- Low carbon steel, also known as mild steel, is the most commonly used type of carbon steel.

It contains less than 0.3% carbon and is relatively soft and easy to form.

It has a tensile strength of around 400 MPa and is used in applications such as construction, automotive, and furniture. - Medium carbon steel, with a carbon content ranging from 0.3% to 0.6%, has a higher strength than low carbon steel but is less ductile.

It has a tensile strength of around 700 MPa and is commonly used in forging and structural applications. - High carbon steel, with a carbon content above 0.6%, is the strongest type of carbon steel.

It has a tensile strength of around 1,000 MPa and is often used in applications such as knives, springs, and high-strength wires.

In summary, the strength of carbon steel varies depending on its carbon content and heat treatment, with low, medium, and high carbon steel offering different strength characteristics suitable for various applications. As a reliable carbon steel supplier, Huaxia-steel provides high-quality carbon steel products tailored to meet the specific needs of our clients in the global market.

Frequently Asked Questions (FAQs)

By: Huaxia-Steel – carbon steel supplier

⭐ Is carbon steel a good metal?

Yes, carbon steel is a good metal for many applications. It is a popular choice due to its strength, durability, and cost-effectiveness.

Carbon steel is versatile and can be used in a variety of industries such as construction, manufacturing, and transportation. It can also be easily fabricated, making it a great option for custom designs.

Additionally, the presence of carbon in the steel increases its hardness, making it ideal for applications that require resistance to wear and tear.

However, it is important to consider the specific requirements of each application when choosing a material.

⭐ Is carbon steel safe?

Carbon steel is generally considered a safe metal to use for various industrial applications.

However, the safety of the metal ultimately depends on how it is used and what measures are taken to ensure safe handling and usage. In general, carbon steel is safe to use in construction, manufacturing, and other industrial settings, as long as proper safety protocols are followed.

As with any material, there may be certain risks associated with carbon steel, such as exposure to fumes or dust during welding or cutting. It is important for workers to follow safety guidelines and wear appropriate protective gear when working with carbon steel or any other material.

⭐ Is carbon steel magnetic?

Yes, carbon steel is magnetic.

The magnetic properties of carbon steel are due to its crystalline structure, which contains iron atoms that can be magnetized.

However, the degree of magnetism may vary depending on the amount of carbon in the steel and the specific alloy composition.

Some types of carbon steel may have higher magnetic properties than others, but overall, carbon steel is a magnetic metal. This property makes carbon steel suitable for various industrial applications, including magnetic shielding and magnetic separators.

⭐Is carbon steel non stick?

No, Carbon steel is not a non-stick metal. It is a strong and durable material that is widely used in various industries, including construction, automotive, and manufacturing.

However, carbon steel is prone to rusting, and it can also react with acidic substances, which can affect its surface. Therefore, it is not recommended for use in applications that require a non-stick surface. To prevent rusting, carbon steel can be treated with coatings or finishes, such as paint or galvanizing, which provide a protective layer on the surface. Overall, while carbon steel is a versatile and useful metal, it is not a non-stick material.

⭐ Do carbon steel rust?

Yes, carbon steel can rust.

This is because carbon steel is not inherently resistant to corrosion like stainless steel or other types of steel alloys. When exposed to moisture or oxygen, carbon steel can undergo a chemical reaction that causes rust to form on its surface.

However, certain treatments such as coating, painting, or galvanizing can help protect carbon steel from rusting. It’s important to note that the amount of carbon in the steel can affect how easily it rusts. Higher carbon content can lead to more rusting, so it’s important to consider the specific carbon content of the steel when determining how susceptible it is to rust.

⭐ Is carbon steel toxic?

No, carbon steel is generally considered non-toxic for most applications.

It is widely used in various industries, such as construction, manufacturing, and automotive, due to its strength, durability, and affordability.

However, some types of carbon steel may contain small amounts of toxic elements, such as lead or arsenic, which can be harmful if ingested or inhaled. Therefore, it is important to carefully assess the specific type of carbon steel and its intended use to ensure that it is safe for the intended application. Proper handling, storage, and disposal of carbon steel products are also important to minimize any potential health and environmental risks.

Carbon Steel Vs Steel

Carbon steel and steel are both commonly used metals in a variety of applications. The main difference between the two is the amount of carbon in the metal. Carbon steel has a higher carbon content than regular steel, usually ranging from 0.5% to 2.0%, while steel typically contains less than 0.3% carbon. This higher carbon content makes carbon steel harder and stronger than regular steel, but also more brittle.

Carbon steel is commonly used in the manufacturing of tools, knives, and machinery parts that require high strength and durability. Steel, on the other hand, is often used in construction, automotive, and household appliances. When it comes to price, carbon steel is generally cheaper than steel due to its simpler production process.

In summary, the main differences between carbon steel and steel are the carbon content, strength, and cost. Choosing which metal to use ultimately depends on the specific application and the required properties of the end product.

What is the difference

between steel and carbon steel?

Steel is a broad term that encompasses many different types of alloys, including carbon steel. Carbon steel, as the name suggests, is a type of steel that primarily contains carbon as an alloying element.

The main difference between steel and carbon steel is the amount of carbon present in the alloy. Steel generally contains less than 2% carbon, while carbon steel typically contains between 0.5% and 2.0% carbon.

The higher carbon content in carbon steel makes it stronger and harder than regular steel, but also more brittle and less ductile. Carbon steel is commonly used in the manufacturing of machine tools, cutting tools, and knives due to its hardness and durability. It is also widely used in the construction industry for building structures such as bridges and pipelines.

Another key difference between steel and carbon steel is their corrosion resistance. Carbon steel is susceptible to rust and corrosion, while some types of steel, such as stainless steel, are highly resistant to corrosion. However, carbon steel can be protected from rust and corrosion through the use of coatings, such as paint or zinc.

In summary, the primary difference between steel and carbon steel is the amount of carbon present in the alloy. Carbon steel contains a higher amount of carbon than regular steel, making it stronger but more brittle. Carbon steel is commonly used in manufacturing and construction industries due to its strength and durability.

By: Huaxia-Steel – carbon steel suppliers

Is carbon steel better than steel?

Carbon steel and steel are both widely used in various industries. The main difference between the two is the amount of carbon they contain. Carbon steel has a higher carbon content, typically ranging from 0.5% to 2%, while steel generally contains less than 0.2% carbon.

Whether carbon steel is better than steel depends on the specific application.

Carbon steel is known for its durability and strength, making it an ideal choice for heavy-duty applications such as construction, infrastructure, and industrial equipment. It also tends to be more affordable than other types of steel.

However, carbon steel is not as corrosion-resistant as other types of steel and may require additional coatings or treatments to prevent rust.

On the other hand, steel is often used in applications that require high levels of corrosion resistance or aesthetic appeal, such as in the automotive or appliance industry. It can also be alloyed with other metals to create specialized alloys for specific purposes.

Ultimately, the choice between carbon steel and steel depends on the specific needs of the application. Both materials have their strengths and weaknesses, and it is important to carefully consider the properties required before making a decision.

By: Huaxia-Steel – carbon steel suppliers

Is carbon fiber stronger than steel?

Carbon fiber and steel have different properties and strengths, so it’s not a straightforward comparison to say which one is stronger.

Carbon fiber is known for being extremely strong, lightweight, and stiff, making it a popular material in aerospace and sporting goods industries. However, carbon fiber is also brittle and can be prone to breaking under certain types of stress.

Steel, on the other hand, is heavier than carbon fiber but is known for being incredibly strong and durable. It has a high tensile strength, which means it can withstand significant force without breaking or deforming. Steel is used in a wide range of industries, including construction, automotive, and manufacturing.

So, while carbon fiber may have a higher strength-to-weight ratio than steel, it’s not necessarily “stronger” in all situations.

The choice between carbon fiber and steel often depends on the specific application and the properties needed for the product. It’s important to consider the trade-offs between weight, strength, durability, and cost when choosing between these materials.

By: Huaxia-Steel – carbon steel suppliers

Request A Free Quote

We’d like to work with you

If you require further information about our metal sheet products or architectural projects, please don’t hesitate to leave your contact details and message here.

Huaxia-Steel – carbon steel suppliers will respond within 24 hours to continue the discussion and provide you with any additional information you requires.