Knowledge: What is the quality control process for medium carbon steel and why is it important?

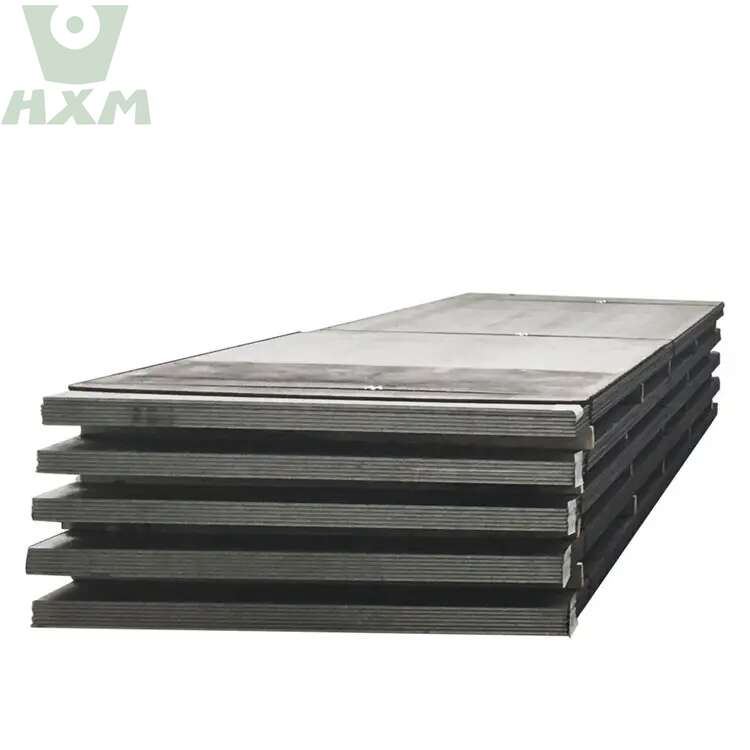

Imagine you’re building a bridge, and you need to rely on high-quality medium carbon steel to ensure its durability and safety. However, how do you know if the steel you’re using is up to the task? That’s where the quality control process comes in. By subjecting the steel to a battery of rigorous tests and inspections, manufacturers can catch any potential flaws before they become a problem. Without proper quality control, a bridge built with faulty steel could spell disaster. So, let’s explore the crucial role of quality control in the medium carbon steel industry and why it’s essential for both manufacturers and consumers alike.

Medium carbon steel is put through a rigorous quality control process to ensure its dependability and safety. Anything less than perfection can have catastrophic results, especially when it comes to structures like bridges that the public relies on for safe passage. To protect people from harm’s way and maintain integrity of our infrastructure, proper testing protocols are essential in all stages of production.

This article will continue to discuss the quality control process of medium carbon steel from the following aspects.

Contents

What are the common quality control standards for medium carbon steel?

Medium carbon steel is like that middle child that nobody talks about. It’s not as hard as high carbon steel, but it’s not as malleable as low carbon steel. That’s why quality control is so important!

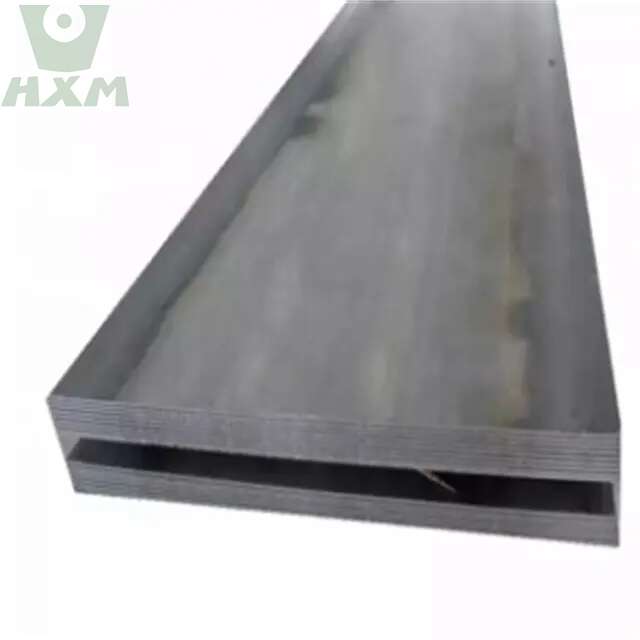

Common quality control standards for medium carbon steel include making sure the steel is free from impurities and defects, ensuring that the carbon content falls within the desired range, and conducting various tests to determine the steel’s mechanical properties, such as tensile strength and hardness.

In short, when it comes to medium carbon steel, quality control is key to making sure you get a product that’s just right – not too hard, not too soft, but juuuust right!

What are the common defects found during the quality control process of medium carbon steel?

Hey there! So, you want to know about the common defects found during the quality control process of medium carbon steel, huh? Well, let me tell you, even the best of us can’t produce a perfect product every single time. There are always some pesky defects that show up during the quality control process.

Common defects in medium carbon steel include surface cracks, porosity, uneven grain size, and improper heat treatment. These defects can weaken the steel’s strength, reduce its durability, and even cause failure in critical applications.

But don’t worry, with proper quality control measures in place, these defects can be minimized or eliminated altogether. So, let’s keep our eyes peeled and our quality control process in check to ensure we produce only the best medium carbon steel products!measures, manufacturers can identify and eliminate these defects before the steel is used.

How do manufacturers ensure that medium carbon steel meets the required quality standards?

You know what they say: the devil is in the details. And that’s especially true when it comes to ensuring that medium carbon steel meets the required quality standards.

Manufacturers have to be on top of their game to make sure that every step of the process, from raw materials to finished product, meets the necessary specifications. They use a variety of techniques and tools, like spectroscopy and ultrasonic testing, to check the steel’s composition, structure, and physical properties. And they keep meticulous records and perform regular audits to ensure that everything is up to snuff.

It’s a complex and challenging process, but it’s worth it to make sure that the end product is strong, reliable, and meets the needs of the people who will use it.

How does quality control impact the cost of medium carbon steel production?

Let’s talk about how quality control impacts the cost of producing medium carbon steel.

First of all, let’s establish that quality control is crucial in ensuring that the medium carbon steel meets the required standards. Without proper quality control measures, there is a higher likelihood of producing defective products, which can lead to costly product recalls, loss of reputation, and even legal disputes.

On the other hand, implementing quality control measures can increase the cost of production. For instance, manufacturers may need to invest in better equipment, hire additional personnel, or conduct more extensive testing. However, these costs are a small price to pay compared to the potential losses incurred from defective products.

Moreover, implementing quality control measures can also result in long-term cost savings. By ensuring that the medium carbon steel meets the required quality standards, the likelihood of costly product recalls is minimized. Additionally, producing high-quality medium carbon steel can lead to greater customer satisfaction and repeat business, ultimately resulting in increased revenue and profitability.

In conclusion, while quality control measures may increase the cost of producing medium carbon steel in the short-term, they are crucial in ensuring that the final product meets the required quality standards and can result in long-term cost savings and increased profitability.

What are the consequences of using low-quality

medium carbon steel in manufacturing or construction?

Using low-quality medium carbon steel in manufacturing or construction can lead to a ton of headaches!

From increased maintenance costs to potential safety hazards, it’s not worth the risk. Imagine building a skyscraper with low-quality steel and having it collapse!

Not only would that be a massive financial hit, but it could also lead to tragic consequences.

Quality control is crucial in ensuring that the steel used in construction and manufacturing meets the necessary standards to prevent any potential disasters.

Conclusion

Quality control is a critical part of producing medium carbon steel that meets the highest standards. From quality assurance checks for common flaws, to verifying and maintaining proper chemical composition – manufacturers understand it would be costly not to have stringent preventative measures in place. The consequences of using substandard products can range from small aggravations like product malfunctions or breakdowns, all the way up to major health risks with no easy fix! Let’s toast good quality control today so we’ll continue reaping its rewards tomorrow!

Request A Free Quote

We’d like to work with you

If you require further information about our metal sheet products or architectural projects, please don’t hesitate to leave your contact details and message here.

Our team of experts will respond within 24 hours to continue the discussion and provide you with any additional information you requires.