Knowledge:What is carbon steel pipe used for?

Have you ever stopped to consider the remarkable role that carbon steel pipes play in our world? They’re the unsung heroes of so many industries, from oil and gas to construction and manufacturing. But did you know that the story of carbon steel pipes is a fascinating one? It all started during the Industrial Revolution, when demand for stronger and more reliable materials was at an all-time high.

Enter carbon steel: the tough and resilient metal that quickly became the go-to choice for engineers and manufacturers. Fast forward to today, and carbon steel pipes are still going strong, supporting critical infrastructure projects and keeping our communities running smoothly. So the next time you turn on the tap or fuel up your car, take a moment to appreciate the humble carbon steel pipe and all that it does for us.

Carbon steel pipes are used to transport fluids and gases in various industries, including oil and gas, construction, and manufacturing. They are strong, durable, and able to withstand high temperatures and pressures. Carbon steel pipes are also commonly used in plumbing, heating, and ventilation systems in residential and commercial buildings.

This article will continue to discuss the carbon steel pipes from the following aspects:

Contents

What are the benefits of using carbon steel pipes over other types of piping materials?

Carbon steel pipes are the workhorse of the piping world, with benefits that are as strong as the pipes themselves.

Unlike flimsy plastic pipes, carbon steel pipes can handle high pressure and extreme temperatures without breaking a sweat. They’re also resistant to corrosion and abrasion, which means they’ll last longer and require less maintenance.

Plus, carbon steel pipes are eco-friendly, as they can be recycled at the end of their life cycle. So if you want a piping material that’s strong, durable, and sustainable, carbon steel is the way to go.

How are carbon steel pipes manufactured and what processes are involved in their production?

Manufacturing carbon steel pipes is like baking a cake: it requires a combination of ingredients, heat, and time.

First, raw materials like iron ore and coal are melted down in a blast furnace to create molten steel.

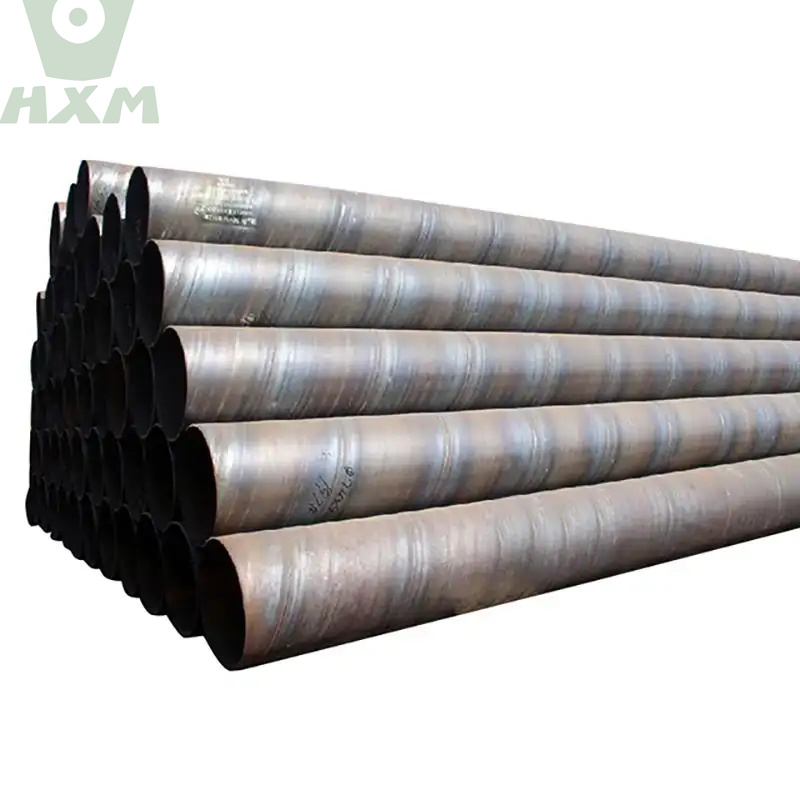

Then, the molten steel is poured into a continuous caster, which forms it into long, thin slabs. These slabs are then rolled into sheets, which are cut into strips and formed into pipes using a variety of methods, such as ERW, LSAW, and seamless.

Finally, the pipes are tested for quality and shipped to their final destination.

What are the different types of carbon steel pipes and how are they used in different industries?

Carbon steel pipes come in a variety of flavors, each with its own unique characteristics and uses.

For example, seamless pipes are ideal for high-pressure applications, while welded pipes are great for structural purposes. LSAW pipes are often used in the oil and gas industry, while ERW pipes are popular in plumbing and heating systems.

Carbon steel pipes can also be coated with materials like epoxy or zinc to improve their performance in specific environments. Whatever the industry or application, there’s a carbon steel pipe that’s right for the job.

How do engineers determine which size and thickness of carbon steel pipe to use for a particular project?

Choosing the right size and thickness of carbon steel pipe is a bit like Goldilocks searching for the perfect porridge: it needs to be just right.

Engineers use a variety of factors to determine the optimal pipe size and thickness for a particular project, including the fluid or gas being transported, the operating temperature and pressure, and the length of the pipe. They’ll also take into account factors like cost and availability when making their decision. It’s a delicate balance, but with the right calculations and expertise, engineers can ensure that the carbon steel pipes used in a project are just right.

What safety measures are required when working with carbon steel pipes in hazardous environments?

Working with carbon steel pipes can be hazardous, especially in environments with extreme temperatures or pressures. That’s why it’s important to take proper safety precautions.

Workers should be trained to handle the pipes safely and wear appropriate personal protective equipment (PPE) like gloves, goggles, and hard hats. They should also follow proper procedures for lifting and moving heavy pipes, and avoid working in confined spaces without proper ventilation.

In addition, regular inspections and maintenance can help prevent accidents and ensure that the pipes remain in good condition. Remember: safety first, pipes second.

What are the common maintenance and repair issues associated with carbon steel pipes?

Carbon steel pipes are tough, but they’re not invincible. Like any material, they can experience wear and tear over time.

The most common issues associated with carbon steel pipe maintenance and repair are corrosion, cracking, and leaking. These problems can be caused by a variety of factors, including exposure to harsh environments, improper installation, and lack of regular maintenance.

The good news is that with proper care and attention, these issues can be addressed and resolved, allowing carbon steel pipes to continue performing their job with efficiency and reliability.

How do carbon steel pipes contribute to environmental sustainability in various industries?

Carbon steel pipes are a sustainable choice for many industries, thanks to their recyclability and long-lasting nature. When carbon steel pipes are no longer needed, they can be easily recycled, reducing waste and conserving resources.

Additionally, carbon steel pipes require less maintenance and replacement than other piping materials, which can save energy and resources in the long run.

By choosing carbon steel pipes, industries can reduce their environmental impact while also reaping the benefits of a strong and reliable piping system.

What are the cost considerations of using carbon steel pipes for large-scale projects?

When it comes to large-scale projects, cost considerations are always at the forefront of decision-making.

While carbon steel pipes may have a higher upfront cost than some other materials, they offer long-term cost savings due to their durability and longevity.

Additionally, carbon steel pipes require less maintenance and replacement than other materials, reducing the overall cost of ownership.

Of course, the specific cost considerations will vary depending on the project and industry, but overall, carbon steel pipes offer a cost-effective and reliable piping solution for large-scale projects.

How do advancements in technology impact the use and development of carbon steel pipes?

Advancements in technology have had a significant impact on the use and development of carbon steel pipes.

New manufacturing techniques and materials have made it possible to produce pipes with greater strength, durability, and resistance to corrosion.

Additionally, advancements in monitoring and control technology have made it easier to detect and address issues with carbon steel pipes before they become major problems.

With each new technological advancement, carbon steel pipes become even more efficient and reliable, making them a top choice for a wide range of industries.

What are the potential future applications of carbon steel pipes in emerging industries?

The potential future applications of carbon steel pipes are virtually limitless, as new industries and technologies continue to emerge.

Some potential areas of growth include renewable energy, such as wind and solar power, where carbon steel pipes can be used to transport energy from the source to the grid.

Additionally, carbon steel pipes are a great option for water transportation and distribution systems, particularly in areas with limited resources.

As new industries and technologies continue to develop, carbon steel pipes will undoubtedly play a crucial role in their success.

Conclusion

In summary, carbon steel pipes are a versatile and reliable choice for a wide range of industries and applications. They offer numerous benefits over other piping materials, including durability, strength, and recyclability. The production of carbon steel pipes involves several processes, including melting, casting, and rolling, and the specific type of pipe used will vary depending on the industry and application. Engineers must carefully consider the size and thickness of the pipe when designing a project, taking into account factors such as pressure and temperature.

While carbon steel pipes require maintenance and repair over time, proper care can extend their lifespan and ensure their continued efficiency. As technology continues to advance, carbon steel pipes will undoubtedly play a critical role in emerging industries and applications, offering sustainable and cost-effective solutions for transporting energy and resources.

Ultimately, carbon steel pipes are a crucial component of many industries, and their strength and reliability make them an essential choice for large-scale projects.

Request A Free Quote

We’d like to work with you

If you require further information about our metal sheet products or architectural projects, please don’t hesitate to leave your contact details and message here.

Our team of experts will respond within 24 hours to continue the discussion and provide you with any additional information you requires.