In the vast world of metalworking and construction, carbon steel sheet and plate are two commonly used materials that often cause confusion due to their similarities. However, as a seasoned metals expert with years of hands-on experience, I can attest to the fact that these two materials, though similar in composition, have distinct differences in their applications, mechanical properties, and fabrication methods.

What is the difference between carbon steel sheet and plate?

Material Composition and Properties

Let’s start with the fundamental aspect: material composition. Both carbon steel sheet and plate are primarily composed of iron with a varying amount of carbon, typically ranging from 0.05% to 2.1% by weight. Carbon is the primary alloying element that determines the mechanical properties of steel, such as hardness, strength, ductility, and weldability. However, the carbon content alone does not distinguish a sheet from a plate.

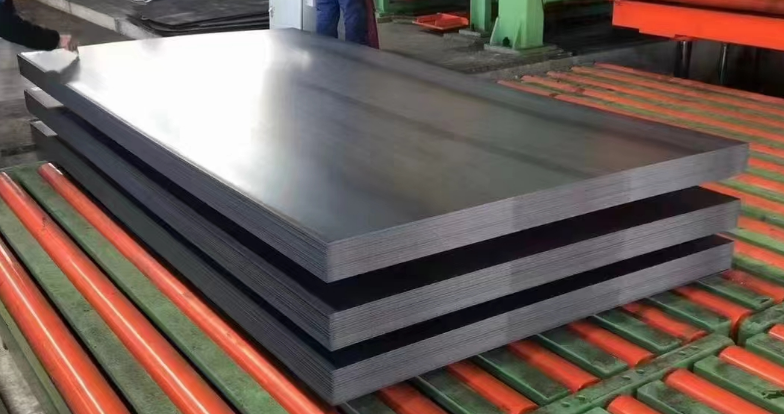

The key difference lies in their thickness. Generally speaking, carbon steel sheet is defined as having a thickness less than 6 mm (0.236 inches), while plate typically has a thickness of 6 mm or greater. This thickness distinction is not arbitrary; it reflects the different applications and fabrication techniques suitable for each material.

Applications

Carbon steel sheet is commonly used in applications where a thin, lightweight material is desired. Its thinner gauge allows for more flexibility and easier forming, making it ideal for uses such as automotive body panels, roofing, and siding. The sheet’s lighter weight also reduces material costs and shipping expenses.

On the other hand, carbon steel plate is typically used in applications that require greater structural integrity and strength. Its thicker gauge provides increased rigidity and resistance to deformation, making it suitable for construction of bridges, buildings, and other heavy-duty structures. Plate is also commonly used in the manufacturing of machinery and equipment where durability and strength are paramount.

Mechanical Properties

Due to their differences in thickness, carbon steel sheet and plate exhibit distinct mechanical properties. Sheet, being thinner, tends to have higher ductility, meaning it can be deformed without breaking. This allows for easier forming and shaping during fabrication processes. However, the thinner gauge also reduces its overall strength and stiffness compared to plate.

Plate, on the other hand, boasts greater strength and stiffness due to its thicker gauge. This makes it more resistant to deformation and able to withstand heavier loads. However, the increased thickness also makes plate less ductile and more difficult to form and shape, requiring more specialized fabrication techniques.

Fabrication Techniques

The differences in thickness and mechanical properties of carbon steel sheet and plate also influence the fabrication techniques suitable for each material.

Carbon steel sheet is often fabricated using processes such as rolling, stamping, bending, and cutting. Its thin gauge allows for easy manipulation using these techniques, making it a versatile material for a wide range of applications. Sheet metalworking tools and machinery, such as brakes and punches, are designed specifically for forming and shaping sheet materials.

Plate, on the other hand, requires more specialized fabrication techniques due to its thicker gauge. Processes such as flame cutting, plasma cutting, and waterjet cutting are commonly used to cut plate into desired shapes and sizes. Plate is also frequently welded to join multiple pieces together, creating larger structures or components. Welding plate requires special attention to ensure proper penetration and fusion of the weld joint, as the thicker material can be more challenging to weld effectively.

Conclusion

In summary, carbon steel sheet and plate, though similar in composition, exhibit distinct differences in thickness, mechanical properties, applications, and fabrication techniques. Understanding these differences is crucial for selecting the appropriate material for a given application.

Thank you for reading our article and we hope it can help you to have a better understanding of the difference between carbon steel sheet and plate. If you are looking for carbon steel sheet and carbon steel plate suppliers and manufacturers online now, we would advise you to visit Huaxia Steel.

As a leading supplier of carbon steel products from Shanghai China, Huaxia Steel offers customers high-quality carbon steel sheets and carbon steel plates at a very competitive price.