Tool Steel

Huaxia-Steel is a leading supplier of tool steel, offering a wide range of high-quality products for global markets. Our tool steel products are widely used in various industries, such as manufacturing, construction, automotive, and more.

At Huaxia-Steel, we pride ourselves on our commitment to quality and reliability. All of our tool steel products are sourced from reputable manufacturers and undergo rigorous quality control testing before being shipped to our customers. We believe in providing only the best products and services to our clients, and we strive to exceed their expectations every time.

Our experienced team of professionals has extensive knowledge of the tool steel industry, and we are dedicated to providing our customers with exceptional service and support. We work closely with our clients to understand their unique needs and requirements, and we offer customized solutions to meet their specific demands.

Whether you are looking for high-speed steel, cold work steel, or any other type of tool steel, Huaxia-Steel has you covered. Contact us today to learn more about our products and services and how we can help you achieve your goals.

REQUEST A QUOTE FOR MORE DETAILS

All You Need To Know About Tool Steel

As a professional buyer in the metal industry, it’s important to know about tool steel. Tool steel is a type of high-quality alloy steel that is used to make tools used in manufacturing processes such as drilling, cutting, and shaping. It is known for its excellent hardness, wear resistance, and toughness, making it ideal for use in high-stress environments.

There are various types of tool steel available on the market, including high-speed steel, hot-work steel, and cold-work steel. Each type has unique properties that make it suitable for specific applications. For example, high-speed steel is ideal for cutting tools, while hot-work steel is ideal for use in high-temperature applications such as forging.

When selecting a tool steel, it’s important to consider the specific requirements of the application, such as the expected stresses and temperatures. At Huaxia-Steel, we offer a wide range of high-quality tool steel products, including popular grades such as D2, A2, O1, M2, and S7. Contact us to learn more about our products and how we can help you meet your tool steel needs.

What is tool steel?

Tool steel is a type of carbon and alloy steel that is specifically designed for manufacturing cutting tools, molds, and dies. It has exceptional hardness, wear resistance, and toughness, making it ideal for high-stress industrial applications. Tool steel is produced using a variety of methods, such as hot forging, rolling, and casting, to achieve its unique properties.

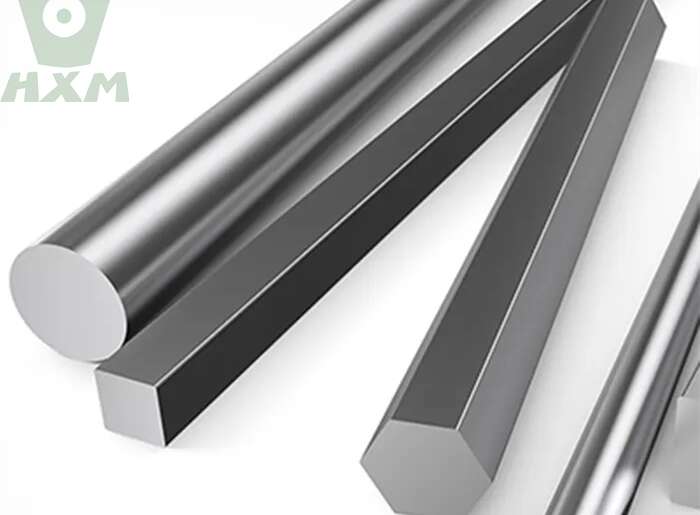

There are many different grades and types of tool steel, each with specific properties and applications. Some common types of tool steel include high-speed steel, cold work steel, hot work steel, and shock-resistant steel. Tool steel is also available in various shapes and sizes, such as round bars, flat bars, and sheets.

As a trusted supplier of tool steel, we at Huaxia-steel offer a wide range of high-quality tool steel products to meet the needs of various industrial applications. We take pride in providing our customers with reliable and cost-effective tool steel solutions, backed by our expertise and commitment to quality.

What is tool steel made of ?

Tool steel is a type of steel that is specially designed for manufacturing tools, such as cutting tools, dies, and molds. It is known for its hardness, toughness, and resistance to wear and tear.

Tool steel is typically made of an alloy of iron and carbon, with additional elements such as tungsten, chromium, vanadium, and molybdenum added to enhance its properties. The carbon content in tool steel is typically higher than in other types of steel, ranging from 0.5% to 1.5%. This high carbon content contributes to the hardness and durability of the steel.

In addition to the carbon content, the specific properties of tool steel are determined by the types and amounts of other alloying elements added to it. For example, tungsten is often added to increase the steel’s hardness and wear resistance, while chromium is added to enhance its corrosion resistance.

Overall, tool steel is a high-performance material that is specifically designed for manufacturing tools that can withstand extreme conditions and repeated use. It is a complex material made of various alloys and elements that are carefully selected to achieve specific properties and meet the requirements of different applications.

What is tool steel used for?

Tool steel is a type of high-quality carbon and alloy steel that is specifically designed for use in the manufacturing of tools and machine parts. It has a high level of hardness, strength, and wear resistance, making it ideal for use in demanding applications that require durability and reliability.

Tool steel is commonly used in the manufacturing of cutting tools, such as drills, taps, and saw blades, as well as dies, punches, and molds. It is also used in the production of machine parts that require high levels of precision and durability, such as gears, shafts, and bearings.

Other applications of tool steel include the production of injection molding components, automotive components, and aerospace components, where high-performance materials are required to withstand the extreme conditions of their respective environments.

Overall, tool steel is an essential material for any industry that requires durable, reliable, and high-performance components. Its unique properties make it an ideal choice for a wide range of applications, and its versatility ensures that it will continue to be a popular choice for years to come.

How hard is tool steel

“How hard is tool steel?” is a common question asked by those looking to work with or purchase tool steel. Tool steel is known for its hardness and ability to withstand high temperatures and pressure. The level of hardness of tool steel can vary depending on the specific alloy and heat treatment used.

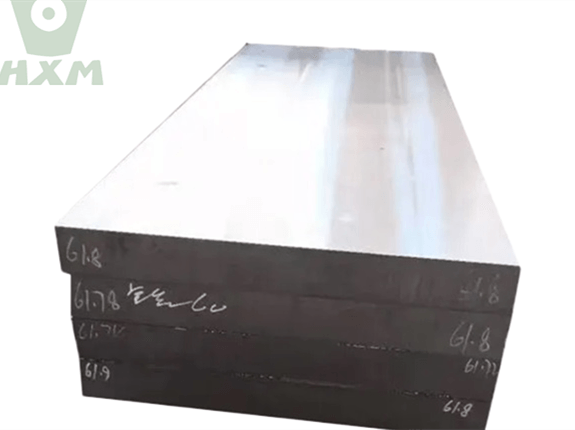

Tool steel is typically rated on the Rockwell C scale, which measures a material’s hardness by how deep an indenter is pushed into its surface. Common tool steel grades can range from 60 to 65 on the Rockwell C scale, which is considered quite hard. However, some specialty tool steels can have hardness ratings of up to 70 or higher.

The hardness of tool steel makes it ideal for use in applications where high wear resistance and toughness are required, such as in the manufacturing of cutting tools, dies, and molds. However, it’s important to note that tool steel’s high hardness can also make it difficult to machine and shape. Overall, the hardness of tool steel plays a crucial role in its performance and usefulness in a wide range of industrial applications.

What is the function of

alloying elements in tool steels?

Alloying elements are added to tool steels to enhance their mechanical properties and performance in specific applications. Chromium, vanadium, molybdenum, tungsten, and cobalt are commonly used alloying elements in tool steels.

Chromium increases wear resistance and corrosion resistance, and is often added to stainless tool steels. Vanadium improves toughness and wear resistance, and is commonly used in high-speed steel (HSS). Molybdenum enhances hardenability, strength, and toughness, and is used in HSS and some tool steels for hot work applications. Tungsten is added to increase hardness and wear resistance, and is commonly used in high-speed and cold work tool steels. Cobalt enhances toughness and high-temperature performance, and is often added to HSS and some hot work tool steels.

The function of these alloying elements in tool steels is to improve their mechanical properties and performance, allowing for better performance in specific applications. The combination and amount of alloying elements used depends on the desired properties of the tool steel, as well as the specific application for which it will be used.

Frequently Asked Questions (FAQ)

⭐ How to temper tool steel?

Tempering is an important process to increase the toughness and reduce the brittleness of tool steel after it has been hardened.

To temper tool steel, the steel must first be heated to a temperature below its critical point and held at that temperature for a period of time, typically ranging from one to several hours. The exact temperature and duration of the tempering process will depend on the desired mechanical properties of the tool steel.

Generally, a lower tempering temperature results in higher hardness and wear resistance, while a higher tempering temperature results in greater toughness and impact resistance. It is important to carefully control the tempering process to ensure that the steel achieves the desired properties for its intended application.

⭐ How to anneal tool steel?

Annealing is a heat treatment process that involves heating tool steel to a specific temperature and then cooling it slowly to make it softer and more workable.

To anneal tool steel, the steel must be heated to a temperature between 1475°F and 1650°F and then held at that temperature for a specific period of time depending on the thickness of the steel. Once the steel has been held at the desired temperature, it must be cooled slowly in a furnace or by burying it in an insulating material such as sand or vermiculite.

Annealing can help to relieve internal stresses in the steel, improve its machinability, and make it easier to work with during subsequent processing steps such as shaping, cutting, or forming.

⭐ How to cut tool steel?

Cutting tool steel requires precision and care to avoid damaging the material or the cutting tool. Here are some tips to help you cut tool steel effectively:

- Use a high-quality saw blade that is specifically designed for cutting tool steel.

- Use a lubricant or coolant to reduce friction and prevent overheating.

- Use a slow cutting speed and avoid applying excessive pressure to the material.

- Use proper safety equipment, such as gloves and eye protection, to protect yourself from any flying debris or metal shavings.

By following these tips, you can cut tool steel with precision and efficiency, helping to ensure that your final product meets your desired specifications.

⭐ Can you weld tool steel?

Yes, it is possible to weld tool steel, but it requires a high level of skill and knowledge.

Tool steel has a high carbon content, making it more difficult to weld than other types of steel. Welding can affect the hardness and toughness of the steel, so it is important to use appropriate techniques and materials to prevent any negative impact on the steel’s performance. Preheating, post-weld heat treatment, and careful selection of welding rods and electrodes are all important factors to consider when welding tool steel.

It is recommended to consult with a professional welder who has experience working with tool steel before attempting to weld it.

⭐ Does tool steel rust?

Yes.

Tool steel is typically made with high levels of carbon and other alloying elements to increase its hardness and durability.

However, this also means that tool steel can be susceptible to rusting if it is not properly maintained or protected. To prevent rust, it is important to store and handle tool steel in a dry environment, and to clean and dry it thoroughly after use.

Additionally, some tool steels may be treated with coatings or other rust-resistant materials to provide added protection. It is important to note that different types of tool steel may have varying levels of rust resistance, so it is important to choose the appropriate type for your specific application.

⭐ More Questions

Where to buy tool steel?

If you’re looking to buy tool steel, Huaxia-Steel is a reliable source.

As a Chinese exproting company specializing in the export of carbon steel, we work with trusted domestic factories to provide high-quality tool steel at competitive prices. Our clients are metal procurement professionals from all around the world, and we understand their need for timely and efficient service.

Whether you need small quantities or large volumes, we can accommodate your needs and ship worldwide. Contact us for a quote and let us help you meet your tool steel needs with our excellent products and exceptional customer service.

Request A Free Quote

We’d like to work with you

If you require further information about our metal sheet products or architectural projects, please don’t hesitate to leave your contact details and message here.

Our team of experts will respond within 24 hours to continue the discussion and provide you with any additional information you requires.